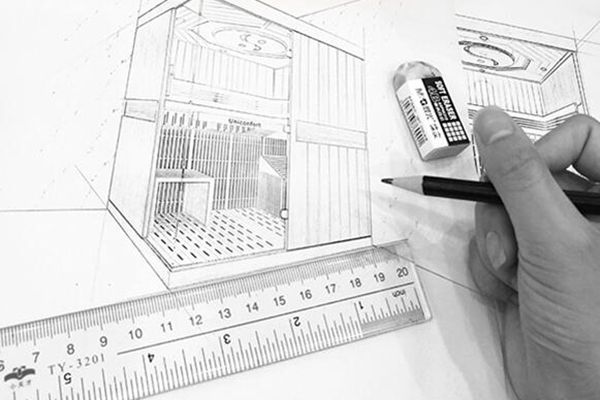

- Innovative Design

- Superior Raw Materials

- Sophisticated Production

- Uncompromising Quality Control

- Request a Quote

Uniconfort has a team with more than 10 years of experience in sauna room design and development, prepared to turn customers’ ideas into reality. As long as the customers provide the idea of a new product, our team can design, develop, produce, and test according to your needs, and complete the final delivery. At the same time, we maintain a strategic partnership with top domestic design agencies, and regularly launch new products that represent market trends every year.

A German customer wanted us to make a unique curved ergonomic backrest in the sauna room, in which the curvature of the upper part should be slightly larger than that of the bottom part. In the case that the customer could not provide engineering drawings, our designers from the engineering department independently completed the design, production, and testing of this backrest according to the average height and body shape of Germans after repeatedly studying the pictures provided by the customer. The German customers were very satisfied after receiving the sauna room and highly appreciate the professional skills of our designers.

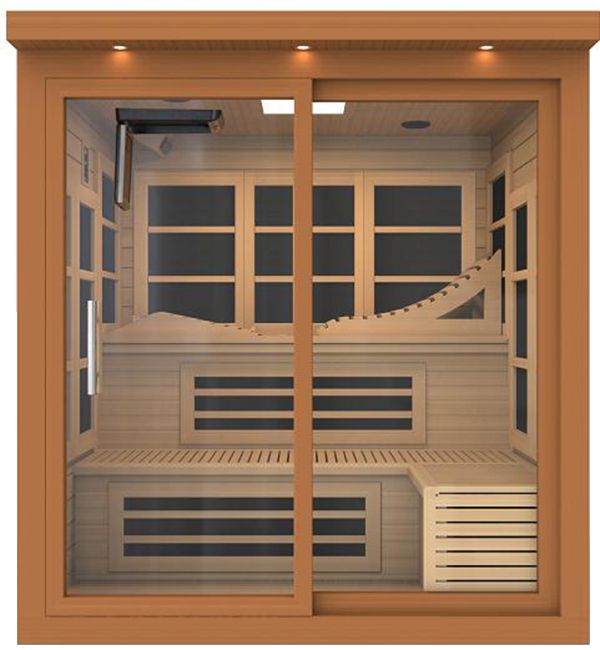

An American customer often complained that the sliding door of the sauna room is noisy and requires a lot of force to move. After carefully studying the structure of the sliding door and combining the large and heavy characteristics of the sauna itself, our engineering team pioneered hanging the sliding door in the sauna, which can transfer most of the gravity of the door to the hanging rail. Thus, by hanging the sliding door, we successfully solved the problems of loud noise and difficulty in pushing the sliding door.

A French customer needed the interchangeability of wood panels for quick installation and simplified warehouse delivery management. Our design team disassembled and installed each wood panel in the sauna room, and each panel was divided into several modules. Each module can be universally interchanged between panels, maximizing the modularization of the sauna room, saving customers' installation time, and improving the efficiency of warehouse delivery.

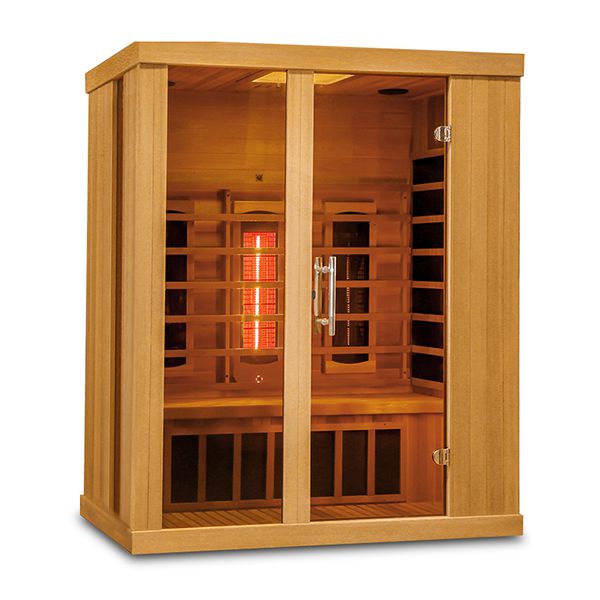

Uniconfort uses imported Canadian wood as the raw material for our sauna rooms. These high-quality woods are over 100 years old, and mainly two types of material are available.

Western red cedar is one of the most valuable species in Canada, which is usually reddish brown. Red cedar has the feature of high natural durability, excellent stability, and long service life, which is not easily deformed. In addition, this wood material is also suitable for high-humidity environments and can repel cockroaches and moths. Moreover, Western red cedar is very popular in the global market due to its non-chemical treatment and pure natural characteristics.

Canadian hemlock has a lighter color, stronger strength and hardness, which is easy to undergo anti-corrosion coating and pressure treatment. This wood material has a straight and fine-lined texture, which is easy to cut and shape. The hemlock does not crack easily due to the bending strength and shear strength, which features the perfect combination of strength and appearance. The Canadian hemlock can undergo a variety of surface coatings, and its natural color and multiple properties lead to prior choice for high-end furniture.

In addition, the wood imported by Uniconfort undergoes a combination of high-frequency drying and microwave drying processes. The drying time of the raw material is 7-15 days, which balances the inner and outer moisture content of the wood, leading to better processing performance, and the wood will not crack easily.

The Uniconfort factory is equipped with 3 modern production lines, more than 60 sets of automation equipment, more than 30 sets of testing equipment, and 3 sets of professional central dust collectors, with an annual production capacity of 30,000 sets. The construction of the second production base has started, and the third production base is the planning stage, with an expected annual production capacity of 80,000 sauna rooms.

Step 1: Wood Processing and Drying

Step 2: Precision Cutting and Sorting

Step 3: Eco-Friendly Finishing

Step 4: Cold Pressing for Durability

Step 5: Triple Hand-Sanding for a Flawless Finish

Step 6: A Balance of Technology and Craftsmanship

Raw material warehouse

Uniconfort uses imported Canadian wood as the raw material for the sauna rooms, and these high-quality woods are over 100 years old.

The wood imported by Uniconfort undergoes a combination of high-frequency drying and microwave drying processes. The drying time of the raw material is 7-15 days, which balances the inner and outer moisture content of the wood, leading to better processing performance, and the wood will not crack easily.

For each sauna room, we have professional staff to inspect processing raw materials, assembling finished products, and shipping in containers to ensure the high quality of manufactured saunas for the customers.

Uniconfort's engineering technology department has set higher standards for production technical guidance compared to other sauna room manufacturing industries. Meanwhile, the Uniconfort's quality department has formulated strict quality control standards based on technical requirements.

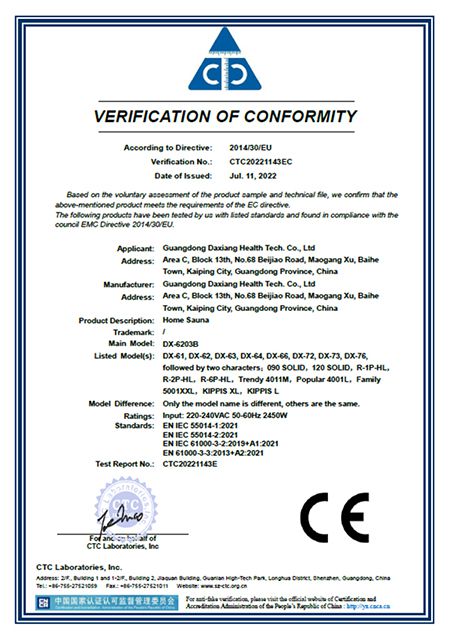

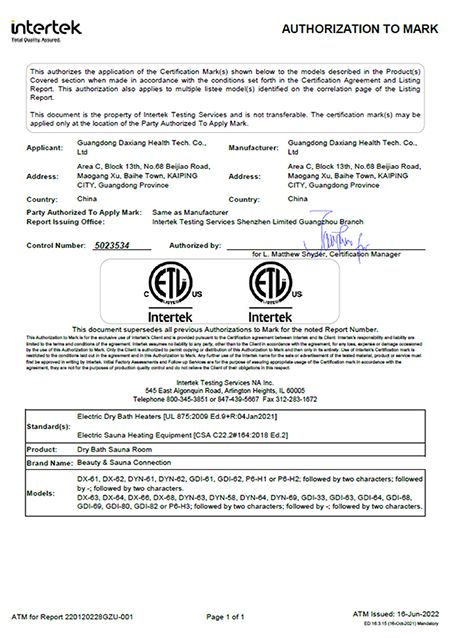

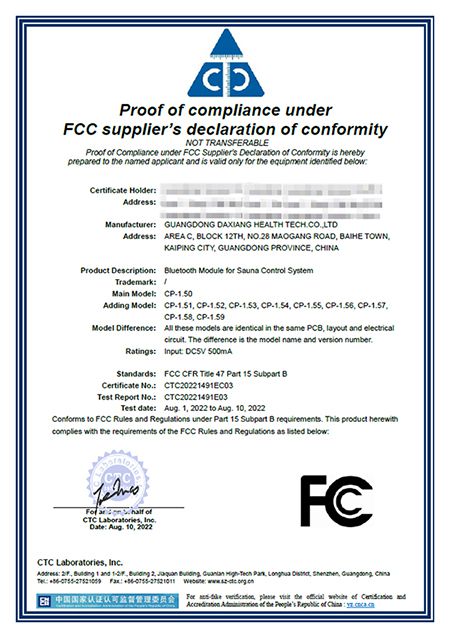

Uniconfort is in strict compliance with ISO9001 and ISO14001 certification to do production and quality control. Our relay cuts both live and neutral wires for extra safety. We have got CE, ETL and FCC certification.